Geschenke für 4-jährige Mädchen

Welches Spielzeug ist bei 4-jährigen Mädchen angesagt. Was können Eltern ihrer Tochter zum Geburtstag, zu Weihnachten und zu Ostern schenken? Bei uns findest du sinnvolle Geschenke für 4-jährige Mädchen. Entdecke ausgewählte Geburtstagsgeschenke, Ostergeschenke und Weihnachtsgeschenke, die für Vierjährige geeignet sind.

Sinnvolles Spielzeug und schöne Geschenke für Mädchen ab 4 Jahren

4-jährige Mädchen haben einen starken Forschungsdrang und entwickeln eine große Neugier auf ihre Umgebung. Sie stellen viele Fragen über das Wieso, Weshalb, Warum und möchten am liebsten alles ganz genau wissen. In diesem Alter werden die Kleinen immer selbstständiger, bestimmte Wesenszüge und Charaktereigenschaften bilden sich heraus und die Entwicklung der Persönlichkeit schreitet rasant voran. Mit der Verbesserung der kommunikativen Fähigkeiten gewinnen Freundschaften mit gleichaltrigen Kindern immer mehr an Bedeutung. Die gemalten Figuren sind jetzt besser zu erkennen und das ein oder andere Kind hat schon gelernt, sich die Schuhe selber zuzubinden. Bei der Auswahl der Geschenke müssen Eltern jetzt immer mehr auf spezielle Wünsche ihrer 4-jährigen Kinder eingehen. Wir haben ein paar Tipps für dich gesammelt, welches Spielzeug bei Mädchen in diesem Alter besonders angesagt ist und mit welchen Spielzeug du positiven Einfluss auf die Entwicklung deiner Tochter nehmen kannst. Finde schöne Weihnachtsgeschenke, Geburtstagsgeschenke und Ostergeschenke in unserer erlesenen Zusammenstellung.

Checkliste: Spielsachen und Geschenke für 4-jährige Mädchen

- Das gemeinsame Spielen mit anderen Kindern wird immer wichtiger. Themenspielzeug gewinnt an Bedeutung.

- Gesellschaftsspiele mit den Eltern und anderen Kindern wird ab dem 4. Lebenjahr zu einer beliebten Freizeitbeschäftigung. Brettspiele, Kartenspiele und Geschicklichkeitsspiele sind sinnvolle Geschenke zur Förderung der motorischen und geistigen Entwicklung der Mädchen.

- Outdoor-Spielsachen wie Ringwurfspiele und Tretroller födern die Motorik, den Gleichgewichtssinn und die Hand-Auge-Koordination.

- Schöne Erlebnisse bleiben in Erinnerung, zum Beispiel eine tolle Party zum 4. Geburtstag oder ein gemeinsamer Ausflug in den Freizeitpark.

Was kann man einem 4-jährigen Mädchen schenken?

Haben die Eltern in den ersten Lebensjahren noch die Spielsachen für ihre Tochter ausgesucht, äußert ihr Kind ab dem 4. Lebensjahr bereits Wünsche zu speziellem Spielzeug, dass es von den Eltern, Großeltern, Onkeln und Tanten zum Geburtstag und zu Weihnachten geschenkt haben möchte. Durch den Umgang mit anderen Mädchen im Kindergarten, im Freundeskreis und durch die Fernsehwerbung bildet sich nun ein erstes Markenbewusstsein heraus und das gewünschte Spielzeug passt sich immer mehr dem weiblichen Geschlecht an. Barbie-Puppen zu einem bestimmten Motto, Baby-Born-Puppen und Figuren zu den Heldinnen aus bestimmten Zeichentrickfilmen stehen auf den Wunschlisten ganz oben. Das Zubehör für diese Puppen und Spielfiguren ist praktisch unerschöpflich und gewinnt für die Mädchen zum Aufbau von Themenwelten immer mehr an Bedeutung. Die Wünsche können bereits so speziell sein, dass Eltern die Geschenke zusammen mit ihren Kindern einkaufen. Dieses Ritual ist sinnvoll, damit die Kleinen mit ihren Geschenken vollends glücklich sind.

Kleine Geschenke für die Tochter zum 4. Geburtstag

Bald ist der 4. Geburtstag der Tochter und die besten Freundinnen sind zu einer kleinen Geburtstagsparty eingeladen. Damit der Tag für das Mädchen lange in schöner Erinnerung bleibt, backt die Mutti Kuchen und schmückt die Wohnung für die Geburtstagsfeier. Bereits mit der Deko kann man kleine Kinderaugen zum Leuchten bringen: Girlanden, Lametta, Luftballons und eine große Vier als aufblasbare Jahreszahl. Natürlich darf auch eine schön verzierte Geburtstagtorte mit 4 Kerzen nicht fehlen, um diesen Tag unvergesslich zu machen. Kleine Geschenke für das Geburtstagskind und ihre besten Freundinnen sorgen für ein tolles Unterhaltungsprogramm: Seifenblasen-Pustefix, Freundschaftsarmbänder und Kinderkameras, mit denen die Kleinen die schönsten Momente der Geburtstagsparty festhalten, sind tolle Spielzeuge, die jede Kinderparty zu einem tollen Erlebnis machen.

Sinnvolle Geschenke für 4-jährige Mädchen

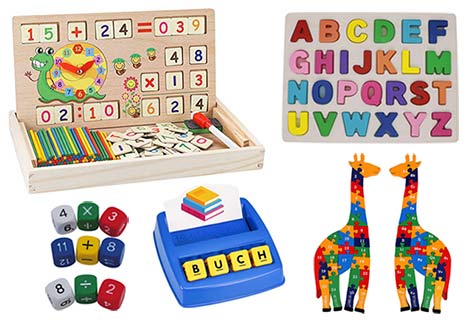

Ungeachtet von speziellen Wünschen bei Puppen und Spielfiguren sollten Brettspiele, Kartenspiele und Lernspielzeug weiterhin als pädagogisch wertvolle Geschenke den Einzug in das heimische Kinderzimmer finden. Denn im Vorschulalter lernen die Kinder schnell und saugen das Wissen nur so in sich auf. Die Spiele vermitteln den Vierjährigen, dass die Einhaltung von Regeln und die Rücksicht auf andere Mitspieler essentiell für das menschliche Zusammenleben sind. Bei der Verbesserung von Feinmotorik und Körperkoordination ist bei Vorschulkindern noch viel Potential vorhanden, dass sich durch Geschicklichkeitsspiele weiter fördern lässt. Für den Fortschritt der sprachlichen Fähigkeiten eignen sich Kinderbücher und spannende Hörspiele als Geburtstags- und Weihnachtsgeschenk. Auch das Vorlesen von Gute-Nacht-Geschichten hat bei 4-jährigen Mädchen noch nicht seine Faszination verloren und ist weiterhin eine sinnvolle Ergänzung für die sprachliche Entwicklung der Vorschulkinder.

- Kleine Geschenke für Kinder unter 5 Euro

- Kleine Geschenke für Kinder unter 10 Euro

- Geschenke für 1-jährige Jungs

- Geschenke für 2-jährige Jungs

- Geschenke für 3-jährige Jungs

- Geschenke für 4-jährige Jungs

- Geschenke für 5-jährige Jungs

- Geschenke für 6-jährige Jungs

- Geschenke für 1-jährige Mädchen

- Geschenke für 2-jährige Mädchen

- Geschenke für 3-jährige Mädchen

- Geschenke für 5-jährige Mädchen

- Geschenke für 6-jährige Mädchen

- Geschenke für 1-jährige Kinder

- Geschenke für 2-jährige Kinder

- Geschenke für 3-jährige Kinder

- Geschenke für 4-jährige Kinder

- Geschenke für 5-jährige Kinder

- Geschenke für 6-jährige Kinder

- Die 41 beliebtesten Spielzeuge für 3-jährige Kinder

- Die 47 beliebtesten Spielzeuge für 4-jährige Kinder

- Das beste Lernspielzeug für Kinder ab 4 Jahren

- Balkonspielzeug: 5 tolle Balkon-Spielsachen für Kinder

- Gartenspielzeug: 50 tolle Outdoor-Spielzeuge für Kinder